Description Also known as "wire walls," 358 mesh panels provide the highest degree of security with excellent see-through visibility. These panels feature a toe and finger-proof profile, with spacing specifications of 4mm x 75mm x 12.5mm, preventing fingers and toes from passing through. Our anti-climb fence is perfect for guarded systems due to its exclusive thickness of anti-cutting materials, making the framework robust, resistant, and difficult to uninstall. Clients can enjoy secured protection and peace of mind with our high-quality anti-climb fence supply.

What is 358 Mesh?

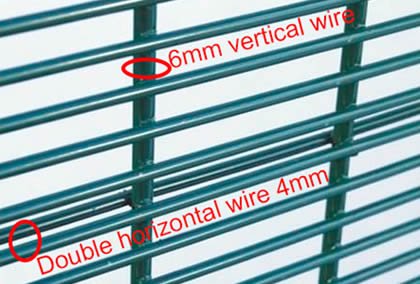

358 Mesh, also known as "prison mesh" or "anti-climb mesh," is a high-security welded mesh panel that provides a significant level of protection. The name "358" comes from its measurement specifications: 3 inches by 0.5 inches (approximately 76.2mm x 12.7mm), with a wire thickness of 8 gauge (4mm).

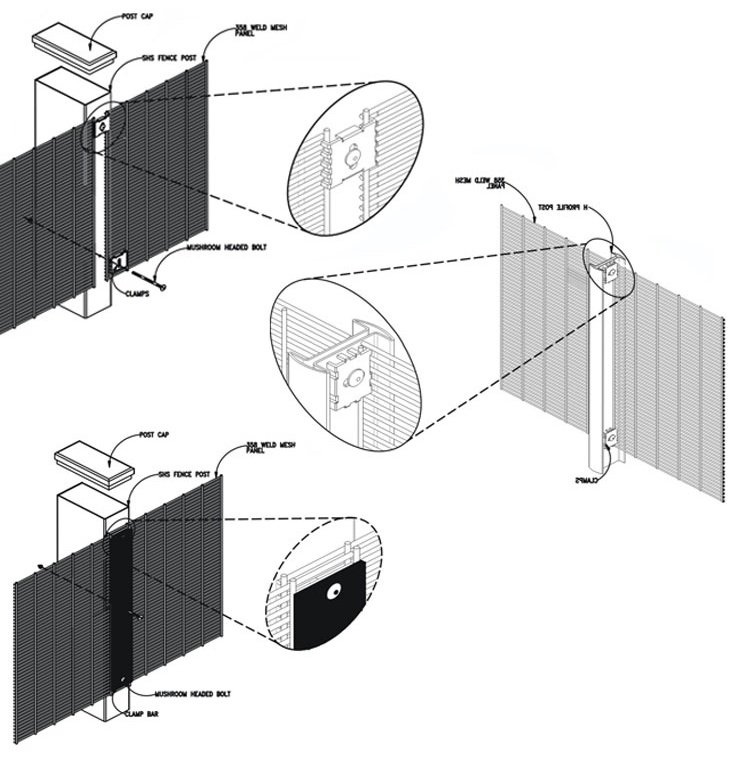

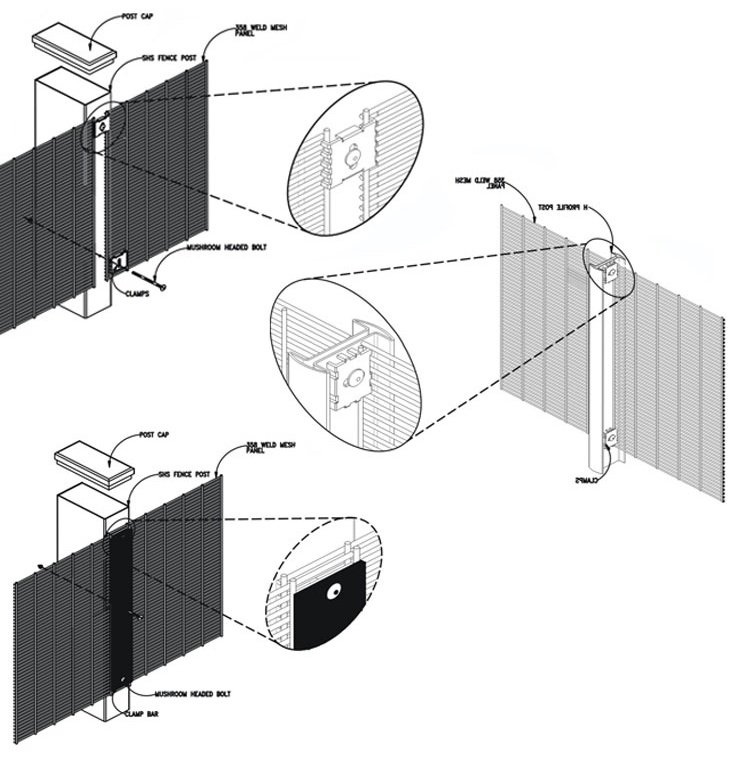

Install of 358 fence panels

|

Some Project Cas

|

|

|

Welding 358 Mesh: Key Considerations for Welders

As a welder working with 358 mesh, also known as "prison mesh" or "anti-climb mesh," it's crucial to understand and adhere to specific practices to ensure the quality and effectiveness of the weld. Here are key considerations to keep in mind:

1. Preparation

- Material Inspection: Ensure the steel wire is free from rust, oil, and other contaminants that could affect the welding process.

- Mesh Alignment: Properly align the mesh panels to ensure uniformity and precision during welding. Misalignment can lead to weak points and reduce the overall strength of the fence.

2. Welding Technique

- Consistency: Maintain a consistent welding pattern to ensure each joint is equally strong. Inconsistent welding can create weak spots that compromise the fence's integrity.

- Heat Settings: Use appropriate heat settings based on the wire diameter (typically 4mm for 358 mesh). Too much heat can cause warping, while too little can result in weak welds.

- Welding Speed: Control your welding speed to ensure proper penetration without burning through the wire. Practice to find the optimal speed that balances penetration and weld quality.

3. Safety Precautions

- Protective Gear: Always wear appropriate protective gear, including welding helmets, gloves, and aprons, to safeguard against sparks and heat.

- Ventilation: Ensure adequate ventilation in the welding area to avoid inhaling fumes, which can be hazardous to your health.

4. Quality Control

- Visual Inspection: After welding, perform a thorough visual inspection of each joint to ensure there are no cracks, gaps, or inconsistencies.

- Strength Testing: Test the welded joints for strength and durability. This can involve applying pressure to ensure the welds hold up under stress.

5. Post-Welding Treatment

- Cleaning: Clean the welded joints to remove any slag or residue. This helps in preparing the mesh for any additional treatments like galvanizing or powder coating.

- Surface Treatment: Apply appropriate surface treatments such as hot-dip galvanizing, powder coating, or PVC coating to enhance the anti-corrosion properties of the 358 mesh.

6. Common Issues and Troubleshooting

- Warping: If the mesh panels warp during welding, check the heat settings and adjust accordingly. Warping often occurs due to excessive heat or improper alignment.

- Incomplete Welds: Ensure your welding technique and speed are adequate to avoid incomplete welds. Re-weld any joints that do not meet the required standards.

7. Documentation and Reporting

- Record Keeping: Maintain detailed records of the welding process, including settings, techniques used, and any issues encountered. This documentation can help in troubleshooting and improving future welds.

- Feedback: Communicate with your team and supervisors about any challenges or suggestions for improving the welding process.

Installation of 358 Mesh Panels

We provide detailed installation guides for our 358 wire mesh fence panels, ensuring proper setup and security.

Applications

358 mesh panels are ideal for various applications, including residential, commercial, and industrial properties, as well as public spaces and high-security areas.

Specifications

Panel Specifications

| Parameter |

Details |

| Panel Height |

1.8m, 2.1m, 2.4m, 3m |

| Panel Width |

2.2m, 2.4m, 3m |

| Hole Size |

12.7 x 76.2mm, 12.5 x 75mm |

| Wire Thickness |

4.0mm |

| Post Length |

2700mm, 3000mm, 3600mm |

| Post Size |

60 x 60mm, 60 x 80mm, 80 x 80mm |

| Material |

Steel wire |

| Surface Treatment |

Powder-coated or PVC coated |

|

358M-01: Anti-cutting 358 mesh fencing |

358M-02: Anti-climbing 358 mesh fencing |

|

358M-03: 358 fence panel with mesh size length 76.2 mm |

358M-04: 358 fence panel with mesh size height 12.6 mm |

Popular Specifications of 358 Mesh Panels

| Wire Diameter |

Mesh Size |

Panel Width |

Panel Height |

Post Height |

Fitting |

| 3.0mm |

12.7 x 76.2mm |

2900mm |

1000mm |

1400mm |

Flat Plate |

| 3.5mm |

12.7 x 76.2mm |

2950mm |

1200mm |

1600mm |

Flat Plate |

| 4.0mm |

12.7 x 76.2mm |

3000mm |

1500mm |

2000mm |

Flat Plate |

| 4.0mm |

12.7 x 76.2mm |

3050mm |

1800mm |

2300mm |

Flat Plate |

| 4.0mm |

12.7 x 76.2mm |

2900mm |

2000mm |

2500mm |

Flat Plate |

| 4.0mm |

12.7 x 76.2mm |

2950mm |

2200mm |

2800mm |

Flat Plate |

| 4.0mm |

12.7 x 76.2mm |

3000mm |

2400mm |

3000mm |

Flat Plate |

| 4.0mm |

12.7 x 76.2mm |

3050mm |

3000mm |

3800mm |

Flat Plate |

Anti-Corrosion Treatments

358 mesh panels offer excellent value for performance, durability, and appearance, with various surface treatments to enhance anti-corrosion properties:

- Hot-Dipped Galvanized After Fabrication

- Galvanized Material Fabricated, Then Powder Coated & PVC Coated

- Hot-Dipped Galvanized After Fabrication, Then Powder Coated & PVC Coated

The powder materials from AkzoNobel and Dupont provide strong resistance to corrosion and ultraviolet radiation, with a double coating layer ensuring a lifespan of over 10 years.

|

358M-05: When install 358 fence on post need overlapped 75 mm minimum at each post |

358M-06: Black 358 mesh fencing used for protection of residential. |

|

358M-08: Green color powder coating 2D security fencing with 6 mm vertical wire and 4 mm double horizontal wire |

358M-09: Details of 2D security fencing panel installed on post |

Surface Treatment Specifications

| Surface Type |

Min |

Max |

| Electric Galvanized |

20g/m² |

60g/m² |

| Hot-Dipped Galvanized |

35g/m² |

700g/m² |

| Powder Sprayed Coating |

100μm |

120μm |

| PVC Coated |

450μm |

650μm |

Color Options 358 mesh

We offer 358 mesh panels in every RAL color to match your corporate design, including:

- Dark Green RAL6005

- Pure White RAL9010

- Stone Grey RAL7030

- Jet Black RAL9005

- Anthracite Grey RAL7016

- Other RAL colors are available upon request

Advantages

- Factory-Direct Price

- 20 Years of Manufacturing Experience

- High Quality

- Quick Shipping Within 7 Days

- OEM Accepted

- 7-Day Money-Back Guarantee

- Installation Guide Provided

Packaging & Shipping 358 mesh

Our 358 mesh panels come with optimal value for performance, durability, and appearance. The wire fence is composed of quadrate posts and high-strength welded wire fence, with strong erosion resistance and anti-ultraviolet properties. 358 mesh panels are connected by a screw flat bar, making installation straightforward and convenient. The anti-cutting design provides robust protection against climbing and destruction.

Choose our 358 mesh panels for a reliable, high-security fencing solution that combines strength, durability, and excellent visibility.

358 mesh, also known as "prison mesh" or "anti-climb mesh," is a top-tier security solution designed to offer maximum protection. Its small mesh aperture and robust wire construction make it nearly impossible to climb or cut, ensuring high security for various applications. With excellent visibility, durability, and versatility, 358 mesh panels are ideal for high-security environments such as prisons, military sites, airports, and industrial facilities. Its ability to withstand harsh conditions and physical impacts, combined with customizable specifications, makes 358 mesh a reliable and effective choice for safeguarding sensitive areas.