The 358 welded wire mesh fence is the top choice for security fencing. It is ideal for places that need the highest security, like prisons, airports, and military bases. This fence style provides the best protection against climbing and attacks. Even with its high security, the fence allows clear visibility along its length.

When welding 358 welded wire mesh fence panels, it’s essential to take specific precautions to ensure strong and durable welds while maintaining the integrity of the material. Here’s what you should keep in mind:

1. Surface Preparation

- Clean the Area: Ensure the surfaces to be welded are clean and free from rust, dirt, oil, or any other contaminants. Use a wire brush, grinder, or chemical cleaner to prepare the area.

- Remove Galvanization: If the panels are galvanized, remove the galvanization in the welding area to prevent toxic fumes and ensure a clean weld. You can do this using a grinder or chemical stripping agent.

2. Welding Method

- Choose the Right Welding Technique: MIG (Metal Inert Gas) welding is generally preferred for 358 mesh panels due to its precision and control. TIG (Tungsten Inert Gas) welding is also an option, especially for more delicate work.

- Use Proper Settings: Adjust the welding machine to the appropriate voltage and wire speed based on the thickness of the material (typically 4mm for 358 mesh). This ensures a strong and consistent weld.

3. Safety Measures 358 welded wire mesh fence

- Wear Protective Gear: Always wear appropriate safety gear, including a welding helmet, gloves, and protective clothing to guard against sparks, UV radiation, and fumes.

- Ensure Ventilation: Work in a well-ventilated area to avoid inhaling any fumes, especially when welding galvanized steel, which can produce harmful zinc oxide fumes.

4. Welding Process

- Apply Steady Pressure: Maintain a steady hand and consistent pressure when welding. This helps create a strong, even weld that fully penetrates the material.

- Avoid Overheating: Do not overheat the material, as this can weaken the metal and cause warping. Use short welding bursts (also known as “stitch welding”) to manage heat.

- Check Weld Quality: After welding, inspect the welds to ensure there are no gaps, cracks, or weak spots. The welds should be smooth and uniform.

5. Post-Welding Care

- Clean the Welds: After the 358 welded wire mesh fence welding is complete, clean the weld area to remove any slag, spatter, or residue. This prepares the surface for any finishing processes.

- Re-Galvanize if Necessary: If you removed galvanization before welding, apply a cold galvanizing spray or zinc-rich primer to the welded area to restore corrosion resistance.

- Inspect the Panel: Finally, inspect the entire panel to ensure it retains its shape and strength. Correct any issues before installation.

Features of 358 Anti-Climb Fence

The 358 anti-climb fence offers several key features. The small opening holes prevent anyone from climbing, as even fingers cannot fit through. The narrow holes also stop bolt cutters and wire cutters from cutting through the fence. Strong welded points ensure that the fence holds up against both human and natural forces. The smooth surface gives the fence a neat, decorative look. Galvanized and PVC-coated panels ensure long-lasting durability.

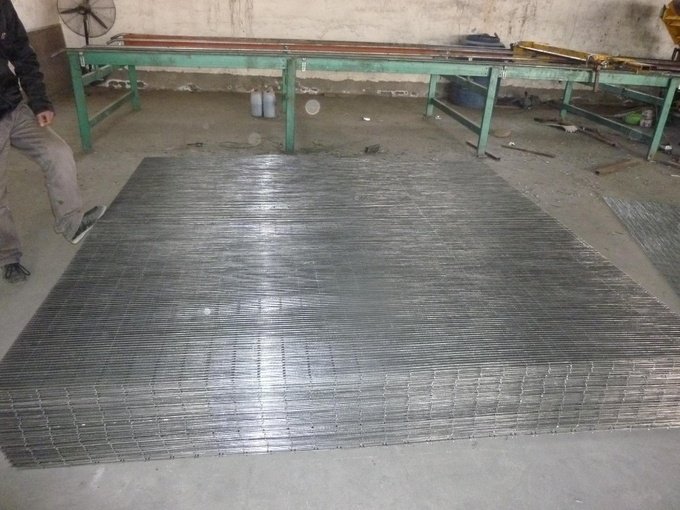

Specifications of 358 Welded Wire Mesh Fence

| Specification |

Details |

| Mesh Dimensions |

76.2mm wide by 12.7mm high |

| Horizontal Wire Diameter |

4mm |

| Vertical Wire Diameter |

4mm |

| Mesh Configuration |

Single horizontal and vertical wires, welded at each intersection |

| Standard Finish |

Hot-dip galvanized and polyester powder coated (Grey RAL 7023; Green RAL 6005; White RAL 9010; Anthracite RAL 7016) |

| Non-Standard Finish |

Wide range of RAL colors available on request |

| High |

Wire Diameter |

| 1270mm |

4.0mm |

| 1500mm |

4.0mm |

| 1800mm |

4.0mm |

| 2000mm |

4.0mm |

| 2135mm |

4.0mm |

| 2440mm |

4.0mm |

| 3000mm |

4.0mm |

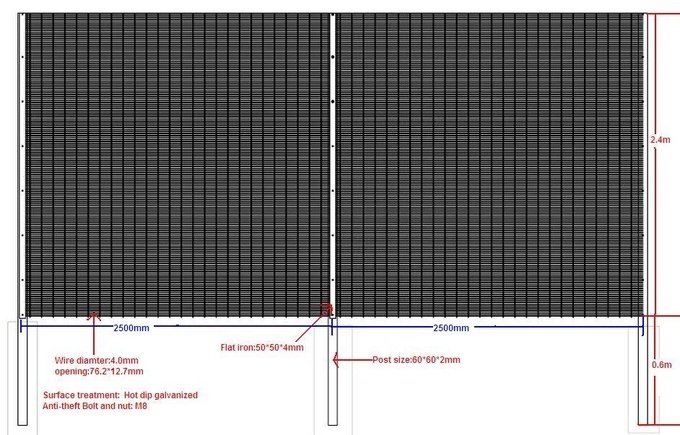

Installation and Additional Details

The 358 welded wire mesh fence uses 4.0mm diameter steel wires. The mesh opening is 76.2×12.7mm, providing maximum security. Posts measure 60×60mm and come in 2.0mm or 3.0mm thicknesses. Install the posts with either a base plate or embed them 0.6m underground. The panels connect to posts with flat plates, making installation simple and effective.