Description Barb wire roll serves as a widely used fencing product for security applications, including perimeter protection, land demarcation, and livestock control. You can install it directly on the ground, along fence tops, or arrange it in rows to create an independent physical barrier.

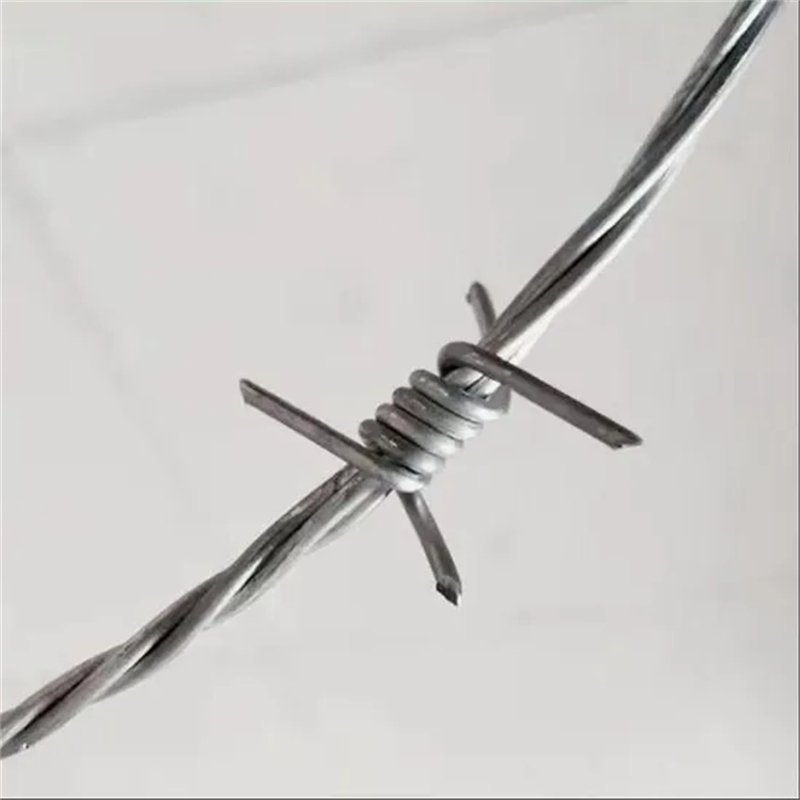

Manufacturers make the product from high-tensile steel wires and twist the barbs around a line wire. To prevent corrosion and extend service life, they treat each barb wire roll with a hot-dipped galvanized zinc coating. The line wire usually has a larger diameter than the barb wire and may consist of one or two strands twisted together.

Construction Details barb wire roll

- The barbs are formed by twisting one or two barb wires around the line wire using a constant torsion system.

- Each barb wire segment creates either two or four sharp spikes, acting as the primary deterrent.

- Double-strand line wire offers improved barb stability and resists displacement.

- On single-strand wire, corrugation prevents barbs from rotating around the line.

Types of Barb Wire Roll

Single-Strand Galvanized Barbed Wire

- Made from one line wire with four-point barbs

- Spacing between barbs: 70 mm to 120 mm

- Line wire diameter: 2.8 mm

- Barb wire diameter: 2.0 mm

- Packaging: 25–45 kg/coil or 100–500 meters/coil

01 High reliability Barbed wire Roll, also known as barb wire, less often bob wire or, in the southeastern United States, bobbed wire, is a type of steel fencing wire constructed with sharp edges or points arranged at intervals along the strand(s). It is used to construct inexpensive fences and is used atop walls surrounding secured property.

02 Surface Treatment

Manufacturers fabricate barbed wire from high-tensile wire as a modern security fencing material. You can install it to frighten and stop aggressive perimeter intruders. Mount piercing and cutting razor blades at the top of the wall to increase deterrence. Special designs make climbing and touching extremely difficult.

03 Woven Type

A barb wire roll or fence wire usually consists of two longitudinal wires twisted together to form a cable. Workers wind wire barbs around one or both of the cable wires at regular intervals.

04 High Security Galvanized/PVC Coated Barb Wire Roll offers a great protection against corrosion and oxidation caused by the atmosphere. Hot-dip galvanizing is stronger than electro-galvanizing.

Double-Strand Galvanized barb wire roll

- Made from two twisted line wires with four-point barbs

- Barb spacing: 75 mm to 100 mm

- Line wire/barb wire diameters: 2.5 mm / 1.70 mm and 2.0 mm / 1.50 mm

- Line wire tensile strength: ≥ 1150 N/mm²

- Barb wire strength: 700–900 N/mm²

- Minimum breaking load (stranded wire): 4230 N

- Packaging: 20–50 kg/coil or 50–400 meters/coil

Galvanizing Options barb wire roll

- All our barb wire rolls are hot-dipped galvanized.

- Zinc surface density options (line wire / barb wire in g/m²):

- 80 / 60

- 114 / 85

- 175 / 147

- 260 / 240

- Note: Electro-galvanized wire has much lower zinc content (~10 g/m²) and rusts within a year. We do not manufacture electro-galvanized wire.

Standard Sizes and Barbed Wire Designs

| Design Number |

Size, Steel Wire Gage |

Diameter of Coated Wire (in./mm) |

Number of Barb Points |

Spacing of Barbs (in./mm) |

Diameter of Barbs, Steel Wire Gage |

Shape of Barbs |

| 12-4-3-14R |

12.5 |

0.099 (2.51) |

4 |

3 (76) |

14 |

round |

| 12-4-3-12R |

12.5 |

0.099 (2.51) |

4 |

3 (76) |

12 |

round |

| 12-2-4-12F |

12.5 |

0.099 (2.51) |

2 |

4 (102) |

12.5 |

flat |

| 12-2-4-13F |

12.5 |

0.099 (2.51) |

2 |

4 (102) |

13 |

flat |

| 12-2-4-14R |

12.5 |

0.099 (2.51) |

2 |

4 (102) |

14 |

round |

| 12-2-5-12F |

12.5 |

0.099 (2.51) |

2 |

5 (127) |

12.5 |

flat |

| 12-4-5-14R |

12.5 |

0.099 (2.51) |

2 |

5 (127) |

14 |

round |

| 12-4-5-14H |

12.5 |

0.099 (2.51) |

4 |

5 (127) |

14 |

half-round |

| 12-4-5-14R |

12.5 |

0.099 (2.51) |

4 |

5 (127) |

14 |

round |

| 13-2-4-14R |

13.5 |

0.086 (2.18) |

2 |

4 (102) |

14 |

round |

| 13-4-5-14R |

13.5 |

0.086 (2.18) |

4 |

5 (127) |

14 |

round |

| 14-2-4-14F |

14 |

0.080 (2.03) |

2 |

4 (102) |

14 |

flat |

| 14-2-5-14F |

14 |

0.080 (2.03) |

2 |

5 (127) |

14 |

flat |

| 14-4-3-14F |

14 |

0.080 (2.03) |

4 |

3 (76) |

14 |

flat |

| 14-4-5-14F |

14 |

0.080 (2.03) |

4 |

5 (127) |

14 |

flat |

| 14-2-5-14R |

14 |

0.080 (2.03) |

2 |

5 (127) |

14 |

round |

| 15-4-5-14R |

14 |

0.080 (2.03) |

4 |

5 (127) |

14 |

round |

| 15-2-5-13F |

15.5 |

0.067 (1.70) |

2 |

5 (127) |

13.75 |

flat |

| 15-2-5-14R |

15.5 |

0.067 (1.70) |

2 |

5 (127) |

14 |

round |

| 15-4-5-16R |

15.5 |

0.067 (1.70) |

4 |

5 (127) |

16.5 |

round |

| 15-4-3-16R |

15.5 |

0.067 (1.70) |

4 |

3 (76) |

16.5 |

round |

Why Choose Our Barb Wire Roll?

Our barb wire roll products are manufactured for high durability, sharp deterrence, and resistance to environmental degradation. All coils are quality-tested, zinc-coated to high standards, and packed for secure transport.

If you need a customized specification or OEM packaging, we can accommodate bulk production with 100,000 pieces/week capacity.