Barbed Wire Fitting Terminology

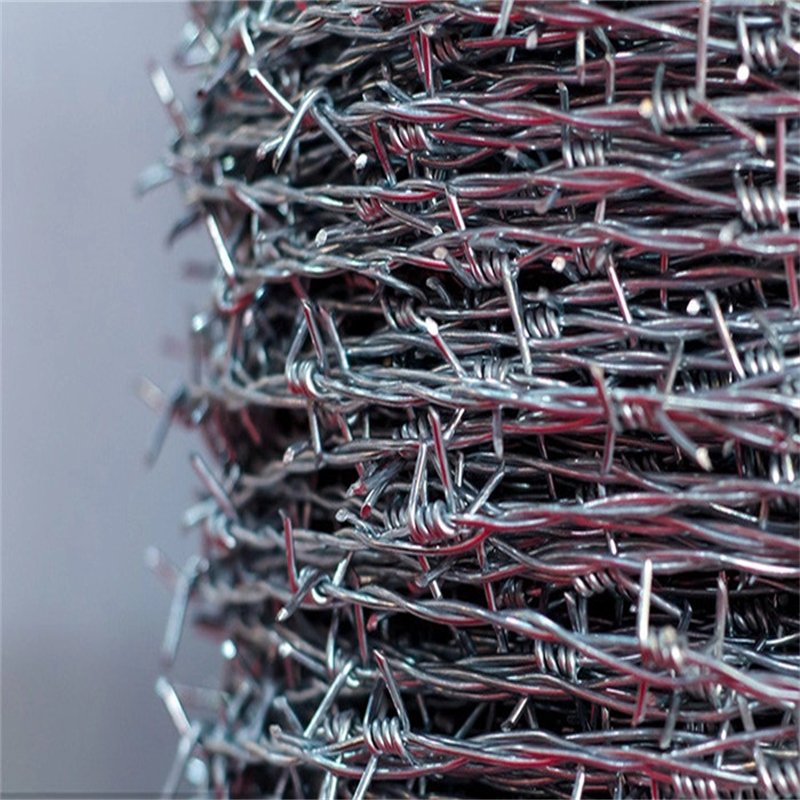

In barbed wire, the barb refers to a short segment of wire with sharp points, created by cutting the wire ends on a bias. These points serve as the key deterrents against intruders, enhancing security by making it difficult to climb or cut through the wire.

Arm

An arm is a post fitting designed to securely hold barbed wire in place. It can be either vertical or angled to support three or more strands of wire. Alternatively, a "V" shaped arm can be used to hold six or more strands, providing extra security.

| Y arm |

Single Arm |

Striaght Arm |

|

|

|

Arm Base

The arm base is a foundational component typically made from aluminum, malleable iron, or steel. This base works in tandem with wire extension arms to create a secure and stable foundation for the wire arms. It is fastened in place with bolts and nuts to ensure a strong hold.

Extension Arm

An extension arm is a galvanized steel or pressed aluminum component that connects with the arm base. It is used to hold the barbed wire strands either vertically or at an inward or outward angle. When paired, extension arms can form a "V" configuration to support multiple strands of barbed wire.

Brace Band

A brace band is a metal strip that fits symmetrically around a post. It is used in combination with a carriage bolt and nut to attach various elements, such as rail ends or truss rod tighteners, to the post. The brace band also serves as a means to secure barbed wire or tension wire to a terminal post.

Tension Band

A tension band is an offset metal strip designed to wrap around a terminal post. It is secured with a carriage bolt and nut to attach the tension bar, ensuring that the wire remains taut and securely fastened.

Barbed Wire Fence Installation: Steps and Tips by BMP

Choosing End and Corner Locations

The first step in installing a barbed wire fence is selecting the end and corner locations. These points are crucial for ensuring the fence remains sturdy and aligned throughout its length.

Installing H-Brace Assemblies

Install wooden posts with H-brace assemblies at the ends of the fence line. At the corners, use double corner braces for added strength. Ensure the posts are buried deep enough for stability, leaving an appropriate height above the ground based on your fence’s requirements.

Securing the First Strand of Barbed Wire

Start by unrolling a short section of barbed wire and securing it around the starting post, wrapping the wire back onto itself. This first strand forms the base of the fence. Unroll the wire toward the opposite end of the fence, keeping it straight.

Tensioning and Cutting the Wire

Use a chain wire strainer at the end of the fence to apply tension to the wire, ensuring it is tight and secure. Once the wire is tensioned, cut it to the appropriate length and fasten it to the post at the desired height.

Aligning the Wire for a Straight Fence Line

Lightly tension the first strand of barbed wire and adjust it to ensure a straight line. Lift the wire to the desired height, allowing it to naturally drop into place. Repeat this process until the wire is aligned straight along the entire fence line. This first strand serves as a guide for installing the remaining strands of wire.

Installing Line Posts

Install line posts at regular intervals along the fence. Adjust the spacing based on the expected pressure on the fence. In high-stress areas, such as feedlots, use heavier posts and place them closer together for added strength and stability.

Securing the Wire to the Posts

Fasten the barbed wire to the posts using wire clips for steel T-posts or staples for wooden posts. When stapling, leave some slack in the wire to allow for expansion and contraction rather than fastening it too tightly.

Reinforcing Strained Posts

For posts in high-stress areas, like dips or elevated sections, reinforce them to handle the wire's tension. Use thicker posts or add bracing as needed. Repeat the installation steps for each additional strand of barbed wire.

Adding Barbed Wire to Chain Link Fences

Attaching Wire Post Extensions

To increase the security of a chain link fence, add barbed wire as a topping. Attach wire post extensions to the corner posts and secure them with screws. Drill holes if the posts lack pre-drilled ones to ensure a firm fit.

Securing the Wire to the Posts

With the extensions in place, attach the barbed wire to the clips on the extensions. Wrap the wire tightly around the posts and use wire ties for added stability.

Tensioning and Extending the Wire

Extend the barbed wire along the top of the fence to the next corner post. Use a wire strainer to tighten the wire until it is taut. Repeat this process along the entire perimeter of the fence.

Clipping Excess Wire

After securing all strands of barbed wire, trim any excess wire. If more strands are required, repeat the process until the fence is fully reinforced.

Conclusion

BMP barbed wire offers a reliable and versatile solution for enhancing security. Conforming to the stringent South African SANS standards, BMP’s barbed wire is known for its sharp edges, corrosion-resistant coatings, and exceptional durability. Whether for agricultural, residential, industrial, or high-security applications, BMP’s provides robust protection against intruders and environmental conditions. With easy installation and low maintenance, BMP is a long-lasting barrier designed to meet your security needs. With our commitment to quality and customer satisfaction, BMP ensures you receive the highest standards in fencing solutions.