Description Barbed wire is a modern security fencing material designed to protect perimeters and prevent intrusions. With its sharp barbs and high-tensile strength, it is a proven choice for enhancing security. Made from galvanized steel or PVC-coated wire, barbed wire is rust-resistant and suitable for harsh environments, including those found in cities like Doha. It is widely used in military zones, government buildings, prisons, and private properties.

How to Choose the Right Barbed Wire for Your Needs

Barbed wire is a trusted and versatile fencing solution used for security, safety, and boundary marking. Choosing the right type depends on your application, material strength, surface treatment, and wire type. This article will help you select the best materials for your requirements, whether for farms, construction sites, military zones, or private properties.

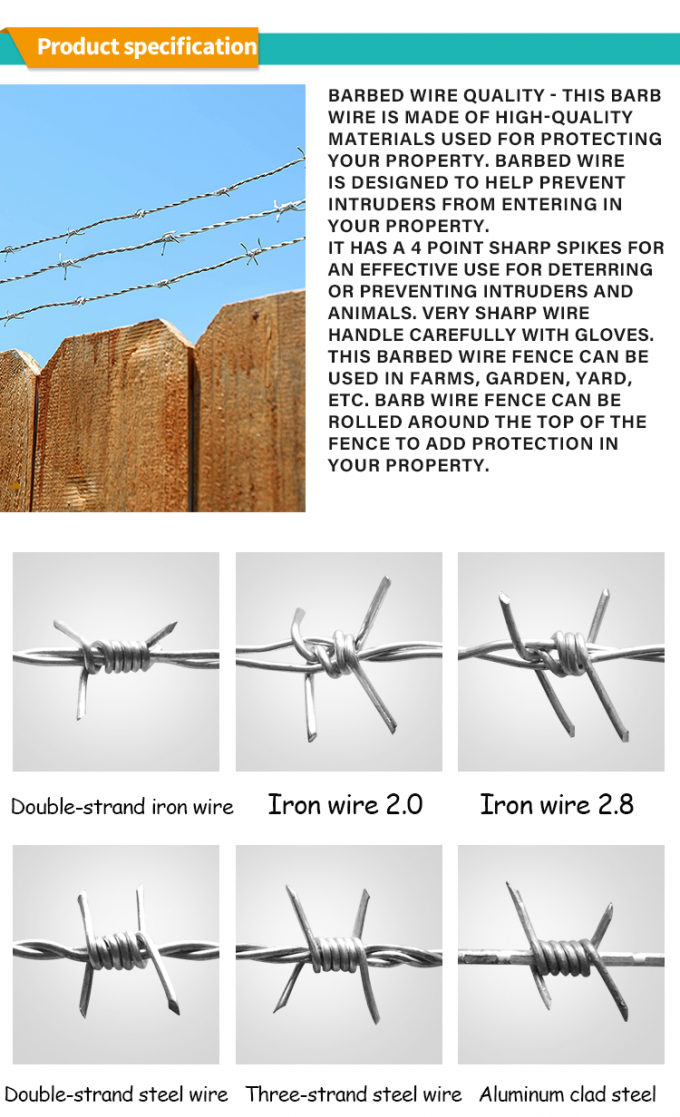

1. Consider the Material

The material of the barbed wire affects its durability and strength.

- Q195 and Q235 Steel Wire: These materials are ideal for standard fencing. They are strong, affordable, and suitable for general security applications.

- High Tensile Steel Wire: This material is best for high-security areas. It is tougher and harder to cut, making it perfect for military zones, prisons, and restricted areas.

Recommendation: For general use, go with Q195 or Q235. For higher security, choose high tensile steel wire.

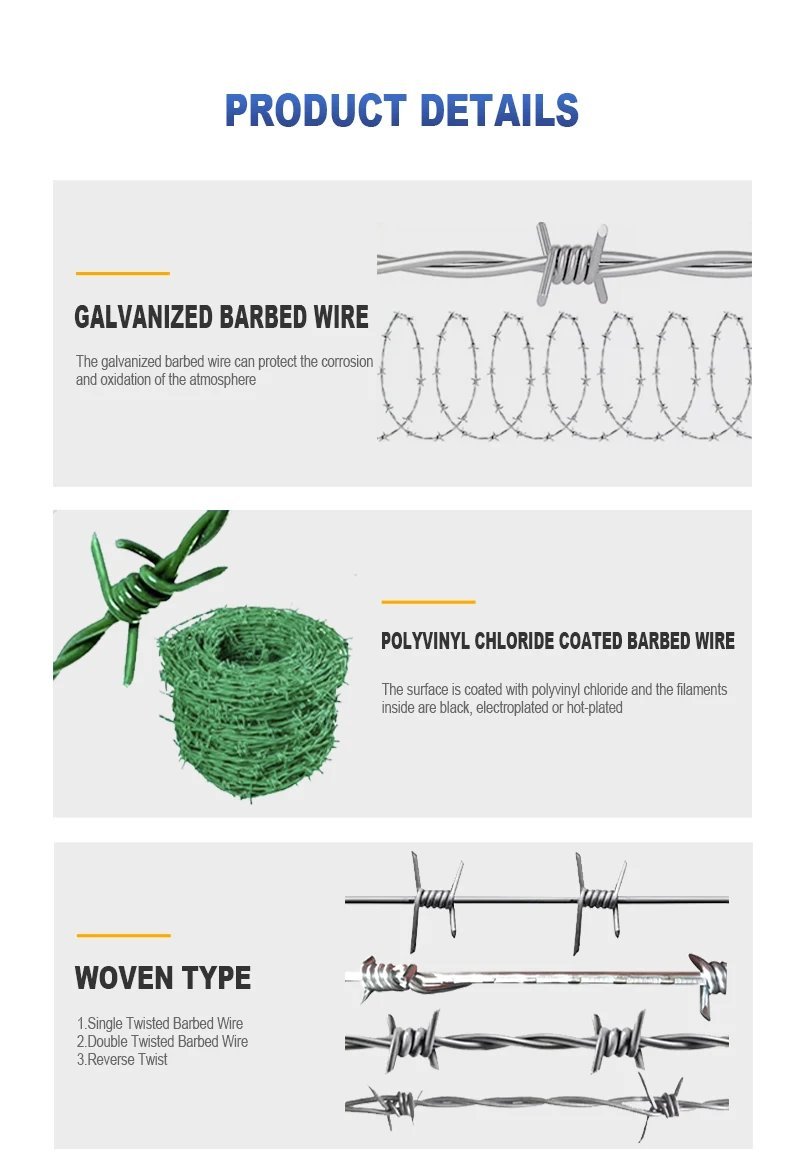

2. Check the Surface Treatment

The surface treatment determines how well the wire resists rust, corrosion, and weather damage.

- Hot-Dipped Galvanized: Offers maximum corrosion resistance with a thick zinc coating. It is ideal for outdoor applications and harsh weather conditions.

- Electro-Galvanized: Provides a thinner zinc layer and is suitable for temporary fencing and indoor use.

- PVC Coated: Adds an extra protective layer with options for various colors like green, blue, and yellow. PVC coating improves visibility and aesthetics while enhancing durability.

Recommendation: Choose hot-dipped galvanized wire for outdoor and long-term fencing, and PVC-coated wire for areas requiring both protection and aesthetics.

3. Understand Tensile Strength

Tensile strength affects how strong and stretch-resistant the wire is:

- Soft Barbed Wire (380–550 N/mm²): Easy to handle and install. Best for residential or light-duty fencing needs.

- High Tensile Barbed Wire (800–1200 N/mm²): Stronger, tougher, and more resistant to cutting or stretching. It is ideal for high-security areas and large boundaries.

Recommendation: Use soft tensile wire for short-term or small-scale applications. Opt for high tensile wire for heavy-duty and long-term fencing.

4. Choose the Right Barbed Wire Type

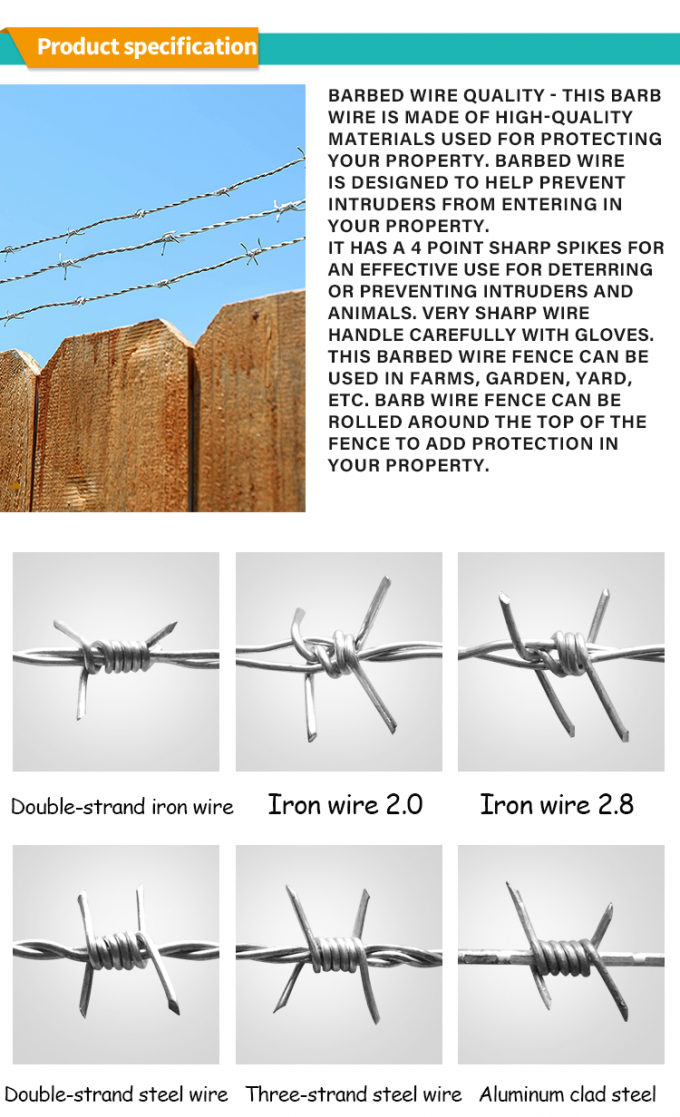

There are three main types of barbed wire to consider:

- Single Strand: A single line of wire with barbs. It is lightweight, cost-effective, and easy to install. Suitable for temporary fencing and low-security needs.

- Normal Twist Double Strand: Two wires twisted together with barbs. It offers added strength and durability for farms, construction sites, and private boundaries.

- Reverse Twist Double Strand: Features a more secure twist pattern that increases tension and durability. This type is ideal for high-security areas like prisons, military zones, and government facilities.

Recommendation:

- Use single strand for temporary fencing.

- Choose normal twist double strand for farms and general security.

- Select reverse twist double strand for maximum strength and security.

5. Packaging Options

The packaging affects transport, handling, and storage.

- Pallet Package: Barbed wire rolls are neatly stacked on pallets for easy loading and transport. Best for bulk orders.

- Bulk Package: Wire rolls are packed together loosely. Suitable for projects requiring quick, on-site handling.

Recommendation: Choose pallet packaging for large projects and bulk transportation. Use bulk packaging for smaller, immediate fencing needs.

Applications of Barbed Wire

Barbed wire is a versatile security solution with numerous applications:

- Military and Government Facilities: Used for perimeter security in military bases, detention centers, and government buildings.

- Prisons and Restricted Zones: Prevents intrusions and escapes in high-security areas.

- Residential Properties: Secures boundaries of cottages, farms, and private homes.

- Construction Sites: Protects materials and equipment from theft.

- Public Safety Areas: Used to control access to dangerous or restricted zones.

Benefits

- High Security: Sharp barbs deter intruders and make climbing nearly impossible.

- Durability: Galvanized and PVC-coated wires resist rust and corrosion for long-term use.

- Cost-Effective: Provides affordable security for large perimeters.

- Easy Installation: Quick to install on walls, fences, or posts without special tools.

- Versatility: Suitable for various terrains and weather conditions.

- Low Maintenance: Requires minimal upkeep after installation.

Packing and Delivery

Barbed wire is carefully packed for safe transport and handling:

- Coil Packaging: Barbed wire is rolled into compact coils.

- Wrapping: Coils are wrapped in waterproof paper or plastic for protection.

- Container Loading: Rolls are stacked securely in containers for delivery.

Customized packaging options are available based on customer requirements.

Galvanized Barbed Wire Specifications

| Gauge (B.W.G.) |

Barb Spacing (mm) |

Approx. Length per Kilo (Meter) |

| 12 × 12 |

76mm (3″) |

6.06m |

| 12 × 14 |

76mm (3″) |

7.33m |

| 12-1/2 × 12-1/2 |

102mm (4″) |

6.92m |

| 12-1/2 × 14 |

102mm (4″) |

8.10m |

| 13 × 13 |

127mm (5″) |

7.98m |

| 13 × 14 |

127mm (5″) |

8.84m |

| 14 × 14 |

152mm (6″) |

10.45m |

Single Twist Barbed Wire Specifications

| Wire Gauge |

Barb Spacing (mm) |

Coating |

Color Options |

| 180# × 180# |

50mm – 150mm |

Galvanized |

Silver |

| 200# × 200# |

50mm – 150mm |

PVC Coated |

Green, Blue, Yellow |

| 220# × 200# |

50mm – 150mm |

Galvanized |

Silver |

| 250# × 220# |

50mm – 150mm |

PVC Coated |

Green, Yellow, Black |

|

simple structure. |

bright and smooth surface. |

can be made into concertina barbed wire for high security. |

Woven bag wrapped package |

Double Twist Barbed Wire Specifications

| Gauge (B.W.G.) |

Barb Spacing (mm) |

Approx. Length per Kilo (Meter) |

Coating |

| 12 × 12 |

76mm (3″) |

6.06m |

Galvanized |

| 12 × 14 |

102mm (4″) |

7.33m |

Galvanized |

| 12-1/2 × 12-1/2 |

127mm (5″) |

6.92m |

Galvanized |

| 13 × 14 |

152mm (6″) |

8.84m |

PVC Coated |

| 14 × 14 |

152mm (6″) |

10.45m |

Galvanized |

| 15 × 15 |

152mm (6″) |

13.89m |

Galvanized |

Types

- Single Twist Barbed Wire: Simple structure with a single strand and sharp barbs.

- Double Twist Barbed Wire: Enhanced strength with double strands twisted for better durability.

Production Process

Material Selection: We choose high-quality galvanized steel wire or PVC-coated iron wire for maximum durability.

Wire Drawing: We draw the steel to achieve the exact diameter needed for the strand and barbs.

Barb Formation: We twist sharp wire around the main strand to form barbs.

Twisting Process: We twist the wires into single or double strand barbed wire.

Galvanizing or Coating: We hot-dip galvanize the wire or coat it with PVC to ensure rust resistance.

Inspection: We check each coil for consistency, sharpness, and durability.

Packing: We roll the barbed wire into compact coils and wrap it for delivery.

Conclusion

Barbed wire is a trusted security solution for protecting perimeters in military zones, prisons, and private properties. Its sharp, durable design ensures maximum security while remaining cost-effective and easy to install. Cities like Al Rayyan have seen increased demand for wire in both public and private sectors due to its reliability and versatility.Whether you need it for national security, construction sites, or residential fencing, wire provides an effective, long-lasting solution for deterring intruders and enhancing safety.Choose barbed wire for your fencing needs and secure your property with a durable, high-strength solution.